The core function of the electronic control system of the sorting machine is to control the comprehensive operation composed of various sorting machines of Yingjie, enabling it to automatically complete the express sorting operation. The entire electronic control system adopts an industrial Ethernet architecture and is mainly composed of four major systems: the main power control system, the trolley control system, the scanning system and the data interface system, with a total power ranging from 20kW to 50kW.

Product Features

The high-end Hardware Has Excellent

Performance

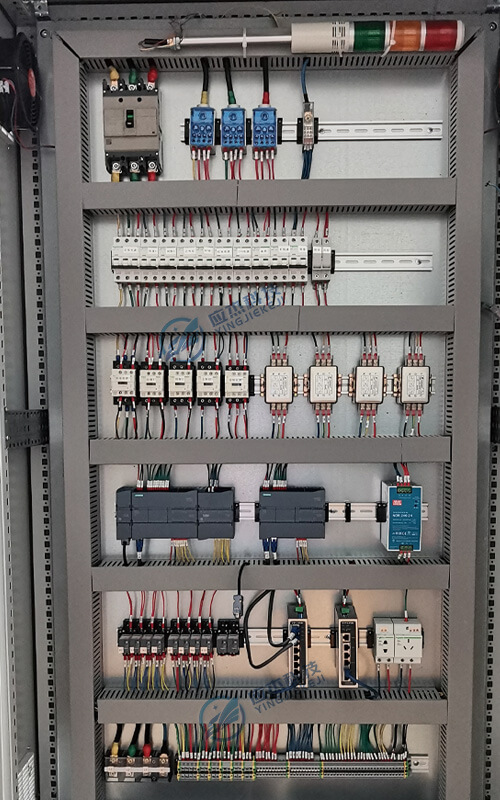

The machine components of the electrical control system adopt designated high-end

brands, including Siemens PLC, Siemens

leakage cables, Schneider switches, Panasonic sliding contact lines, Huawei industrial

switches, etc., to ensure the

efficient and stable operation of the system.

Real-time Communication And Real-time

Monitoring

The communication system adopts 5g wireless communication mode, industrial-grade

communication technology, and an

independent communication channel to avoid signal interference and ensure stability and

smoothness.

Efficient Maintenance Of Independent

Modules

The sorting machine, scanning system, trolley, grid opening and other parts are

independently controlled by modules,

each with an independent IP, enabling rapid inspection and maintenance. Faults are

immediately locked and independently

handled, effectively avoiding system disorder.

Practical Verification Of The

Scientific System

The trolley control system adopts 485 control mode and other comprehensive

optimizations. The scientific control system

has been verified through years of practice, forming an efficient control system with

Yingjie's independent patent,

ensuring the stable and smooth operation of various sorting machines.