Yingjie Technology ring cross belt sorting system is a scheme design plasticity, stable function and high reliability, more flexible structure, more stable operation, higher sorting efficiency of sorting equipment, more suitable for inbound and outbound business large express companies and outlets. At present, there are four types of line bodies widely used, which are single layer single layer single layer single layer single layer double layer single layer double layer sorting system and double layer double layer double layer sorting system.

System Features

1. Modular design with high cost-effectiveness;

2. Highly adaptable with flexible configurations;

3. High sorting efficiency and low mis-sorting rate;

4. Gentle sorting action minimizes impact on goods;

5. Shared use for inbound/outbound operations and multi-carrier compatibility;

6. Seamless integration with client information management systems.

Technical Parameters

| Sorting efficiency | 12,000 – 60,000 pieces/hour |

| Operating speed | 2m/s – 2.5m/s |

| Standard pitch | 600mm |

| Mis-sorting rate | < 0.03% |

| Barcode recognition rate | 99.99% |

| Parcel dimensions | Max. 420mm×650mm×400mm |

| Carrier load capacity | 0.05kg – 15kg |

| Floor space | 800m² – 2,000m² |

| Workforce requirement | 10 – 60 operators |

| Equipment investment | ¥900,000 – ¥4,000,000 (site-specific solutions may vary) |

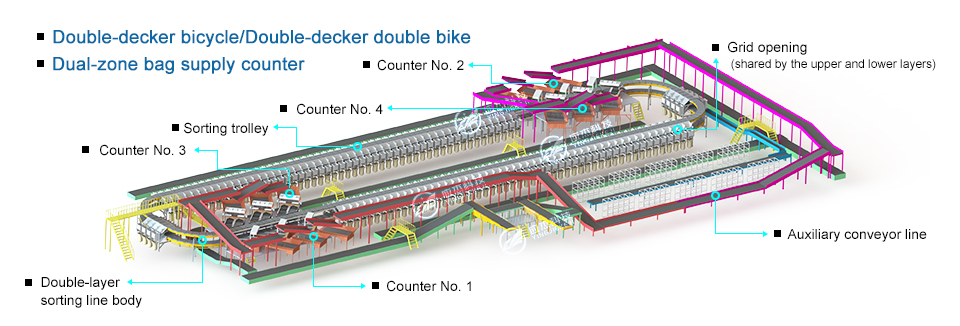

System Structure

It is mainly composed of four parts: supply system, sorting trolley, next part system and control system. Under the coordination control of the control system, the package is imported from the supplier system into the sorting trolley for sorting, and the next part system completes the classification and storage of the physical location of the package, so as to achieve the package sorting function. The modular assembly method is used for flexible configuration, which can adapt to various site requirements.

| Sorting efficiency | 12,000 – 30,000 pieces/hour |

| Operating speed | 2m/s – 2.5m/s |

| Standard pitch | 600mm |

| Mis-sorting rate | < 0.03% |

| Barcode recognition rate | 99.99% |

| Parcel dimensions | Max. 420mm×650mm×400mm |

| Carrier load capacity | 0.05kg – 15kg |

| Floor space | 800m² – 1,500m² |

| Workforce requirement | 10 – 30 operators |

| Equipment investment | ¥900,000 – ¥2,000,000 (site-specific solutions may vary) |

| Sorting efficiency | 30,000 – 60,000 pieces/hour |

| Operating speed | 2m/s – 2.5m/s |

| Standard pitch | 600mm |

| Mis-sorting rate | < 0.03% |

| Barcode recognition rate | 99.99% |

| Parcel dimensions | Max. 420mm×650mm×400mm |

| Carrier load capacity | 0.05kg – 15kg |

| Floor space | 1,000m² – 2,000m² |

| Workforce requirement | 30 – 60 operators |

| Equipment investment | ¥2,000,000 – ¥4,000,000 (site-specific solutions may vary) |

| Sorting efficiency | 30,000 – 60,000 pieces/hour |

| Operating speed | 2m/s – 2.5m/s |

| Standard pitch | 600mm |

| Mis-sorting rate | < 0.03% |

| Barcode recognition rate | 99.99% |

| Parcel dimensions | Max. 420mm×650mm×400mm |

| Carrier load capacity | 0.05kg – 15kg |

| Floor space | 1,000m² – 2,000m² |

| Workforce requirement | 40 – 60 operators |

| Equipment investment | ¥2,000,000 – ¥5,000,000 (site-specific solutions may vary) |

| Sorting efficiency | 30,000 – 60,000 pieces/hour |

| Operating speed | 2m/s – 2.5m/s |

| Standard pitch | 600mm |

| Mis-sorting rate | < 0.03% |

| Barcode recognition rate | 99.99% |

| Parcel dimensions | Max. 420mm×650mm×400mm |

| Carrier load capacity | 0.05kg – 15kg |

| Floor space | 1,000m² – 2,000m² |

| Workforce requirement | 30 – 60 operators |

| Equipment investment | ¥2,000,000 – ¥4,000,000 (site-specific solutions may vary) |